oUR hisTory

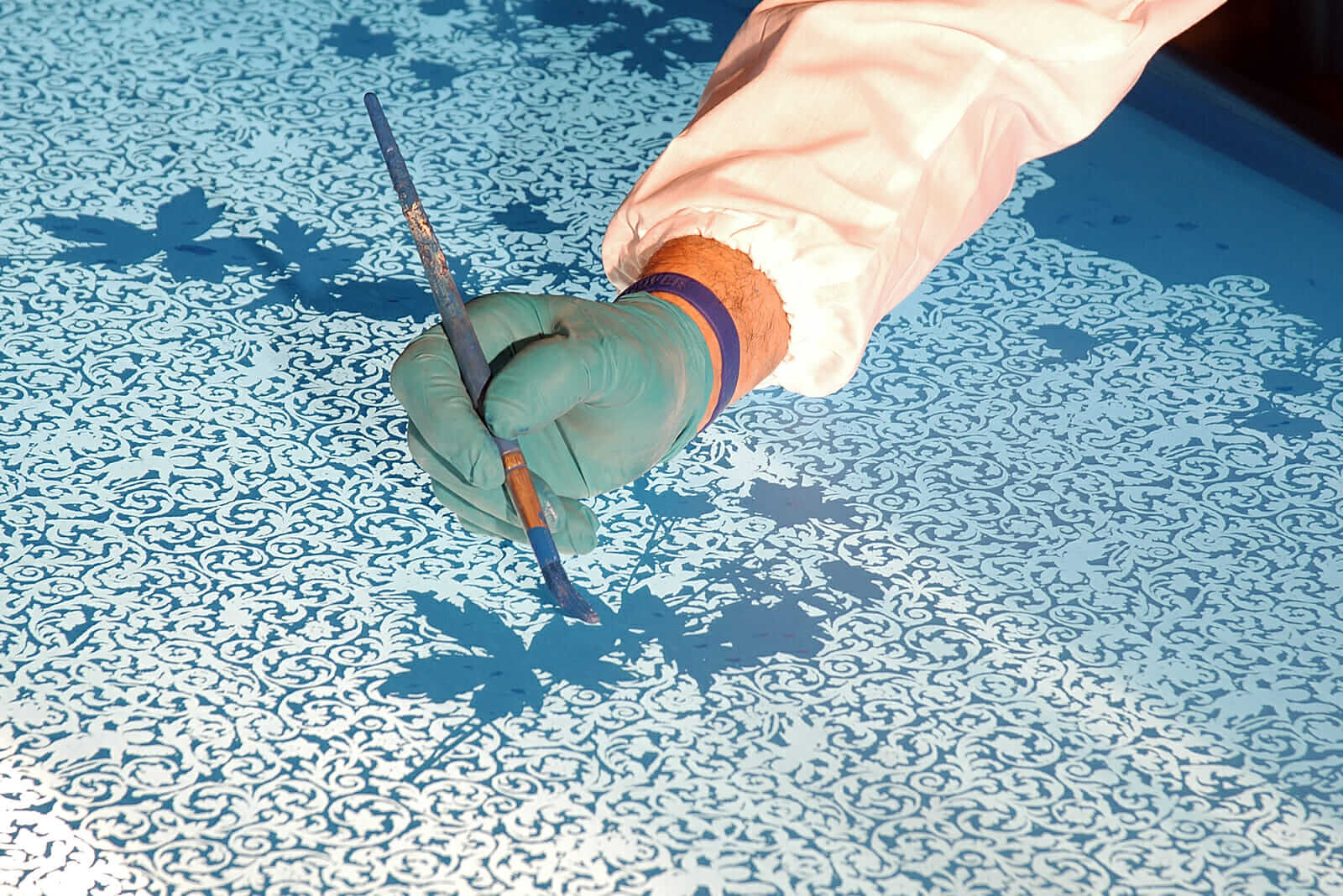

The history of our company began in 1985 cwith Paolo Rigamonti, who started a photoengraving business for textile prints using paintings and cylinders.

The traditional technique required lucids and a manual procedure. However, we invested in digital change to improve accuracy and quality. In the 1990s, responding to market demands, we introduced digital printing for the smaple on fabric. Thanks to the constant research and collaboration with machine manufacturers, we improved the quality of digital printing, becoming a leader in the industry.

Today, we offer a vertical printing service, ensuring quality, speed and experience to our customers, which include renowned international brands. We continue to invest in the evolution of digital printing for environmental benefits, management and product quality.

After 40 years of activity, our history continues with Rigamonti Sofia who for more than 10 years has been working in the company with devotion and passion. Her goal is to operate in the sector with young people in a green waykeeping quality and service.

The traditional technique required lucids and a manual procedure. However, we invested in digital change to improve accuracy and quality. In the 1990s, responding to market demands, we introduced digital printing for the smaple on fabric. Thanks to the constant research and collaboration with machine manufacturers, we improved the quality of digital printing, becoming a leader in the industry.

Today, we offer a vertical printing service, ensuring quality, speed and experience to our customers, which include renowned international brands. We continue to invest in the evolution of digital printing for environmental benefits, management and product quality.

After 40 years of activity, our history continues with Rigamonti Sofia who for more than 10 years has been working in the company with devotion and passion. Her goal is to operate in the sector with young people in a green waykeeping quality and service.

Como: city of silk

The tradition of silk in the Larian territory dates back to 1400, when Ludovico Sforza ordered the cultivation of mulberry for the production of silk.

The industry thrived until the 1970s, when local production surpassed that of China and Japan.. The first silk prints were made with engraved wood swabs, but the spread of photoengravings and later cylinders revolutionized the process. However, The high costs of switchboards and cylinders and stylistic evolution have reduced their use.

Ink-jet printing, born due to the growing demand for designs and variants, has revolutionized the industry, offering short times and low costs without the need for expensive equipment.

The industry thrived until the 1970s, when local production surpassed that of China and Japan.. The first silk prints were made with engraved wood swabs, but the spread of photoengravings and later cylinders revolutionized the process. However, The high costs of switchboards and cylinders and stylistic evolution have reduced their use.

Ink-jet printing, born due to the growing demand for designs and variants, has revolutionized the industry, offering short times and low costs without the need for expensive equipment.

Technology

Our inkjet machines

Fabric preparation

Fabric preparation for ink-jet “a spalmatura”.

Machines with acid colours

Digital machines with acid colors for fabrics such as silks, cashmere, wool, nylon etc

Machines with reactive colours

Digital machines with reactive colors for cottons, modal, velvet, linen etc

Steaming in largo

Steaming in stella

Washing in largo

Washing in barca

Certifications icea